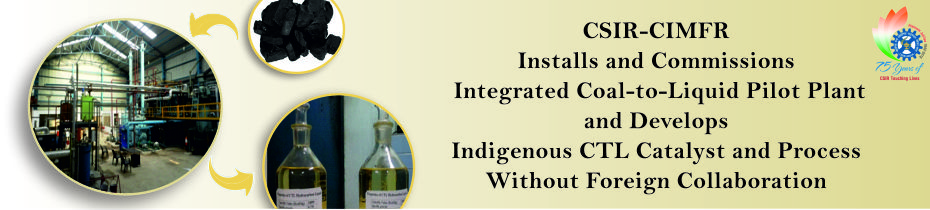

CSIR-CIMFR Installs and Commissions first-of-its-kind Coal to Liquid (CTL) Pilot Plant for Producing Diesel and Gasoline from Coal

The process of converting coal to liquid hydrocarbons, liquid fuels and petrochemicals is called Coal Liquefaction. Coal to Liquid Fuels is commonly called “CTL” or “coal liquefaction”, although “liquefaction” is generally used for a non-chemical process of becoming liquid. Only a few countries could develop this very important technology which is closely guarded.

CSIR-Central Institute of Mining and Fuel Research (CSIR-CIMFR), Dhanbad is striving hard to develop an alternative route to produce diesel/gasoline so as to decrease some burden of importing petroleum crude. Coal can be converted into liquid fuels like gasoline/diesel by indirect liquefaction technique through Fischer-Tropsch route. Indirect CTL technology has been the most successful process till date. India has huge coal reserves and can use some part of coal to convert it to diesel/gasoline. Gasification of coal will produce synthesis gas (a mixture of CO + H2) which can be liquefied to gasoline/diesel equivalent in presence of cobalt/iron based catalysts at higher pressure and temperature.

Very recently, CSIR-CIMFR has successfully installed and commissioned an integrated Coal-to-Liquid pilot plant and developed indigenous CTL catalyst and process without seeking the knowhow from foreign collaborators. The CTL crude produced from this Pilot Plant is having very high calorific value of more than 10899 Kcal/Kg which is more than that of diesel produced from petroleum crude import and it has also very high Cetane number ( > 74.8 ) and low Research Octane Number (RON < 40) which shows its suitability as diesel fuel.

Coal liquefaction is a realistic choice for a country like India, deficient in oil reserves but having plenty of coal reserves. Importing foreign technology without the know-how or collaboration with technology providers is not a permanent solution for the development of CTL technology as India aims at energy security.

CSIR-CIMFR is spearheading research in this crucial strategic sector and in its ongoing endeavour has developed the Technology for Conversion of Coal to Liquid Hydrocarbon.

It is expected that India will continue to import huge amount of crude oil/petroleum products in future. Though India is improving the availability of other fuels like natural gas, however, it will not substantially reduce India’s increasing dependence on imported oil. Under these circumstances, India should utilize its coal reserves for conversion to oil which will enhance India’s oil security. Laboratory scale process has been established by CSIR-CIMFR for conversion of H2 lean syngas to liquid fuel (diesel/gasoline) synthesis.

The pilot plant for Coal-to-Liquid at the CSIR-CIMFR produces 5 L per day liquid hydrocarbon. The institute is seeking partnership for scaling up the developed technology and commercialising it.

{Feature has been uploaded by CSIR (Unit for Science Dissemination), Ministry of Science & Technology, New Delhi}.